Rotary Joint

The zenmax rotary joint can ensure the stable transmission of high-pressure oil to the hydraulic actuator under the high-speed operation condition, making the system stable and reliable The fitting surface between the port plate and the hollow shaft, as well as the fitting surface between the shaft seal and the hollow shaft at the shaft end and tail end were specially processed, which greatly improved the smoothness and hardness of the fitting surface, and greatly extended the service life of the joint. The flatness of its core component, disc valve plate, is 3um, which makes its operation more stable and smooth.

Under the condition of high-speed operation, the ZM200 disc type hydraulic rotating joint can ensure the transmission of high-pressure oil to the hydraulic actuator steadily, make the system run stably and reliably. The fitting surface between the port plate and the central shaft as well as the surface between the shaft seal and the central shaft were processed by ceramic process, which make the smoothness and hardness of the fitting surface are greatly improved, prolong the service life of the joint.

Features

●Precise bearing on both sides, smooth operation.

●The fitting surface made by ceramic technology, wear-resistant, long using life.

●The flow rate up to 640L/min.

●High precision joint, medium should be filtered, cleanliness is not lower than NAS9 grade.

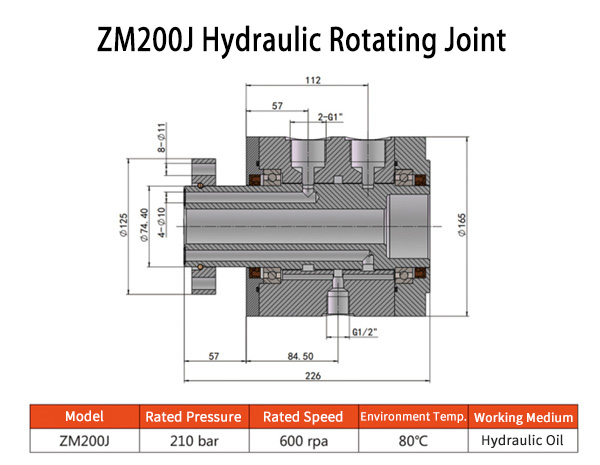

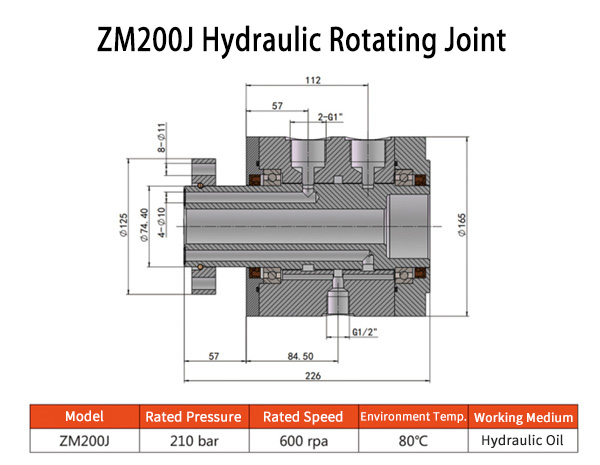

ZM200J hydraulic rotary joint use the small clearance between fixed parts and rotating parts, under the condition of high speed and high pressure to local change the flow area, cause a pressure loss of liquid flow, thus results in a very low leakage and returns to oil tank through the oil drainage port. This kind of sealing structure has high requirements for the geometrical size, surface machining precision and assembly of the parts.

Features

●Precise bearing on both sides, smooth operation.

●Non-contact and non-wear seal design.

●The fitting surface made by ceramic technology, long using life.

●Low turning torque produce less heat.

●High precision joint, medium should be filtered, cleanliness is not lower than NAS9 grade.

●Cause the hollow spindle design of the main shaft, the central part can pass through the displacement sensor and other components.

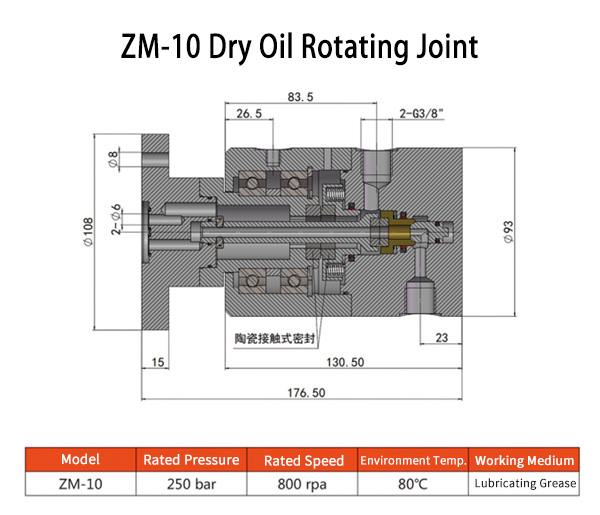

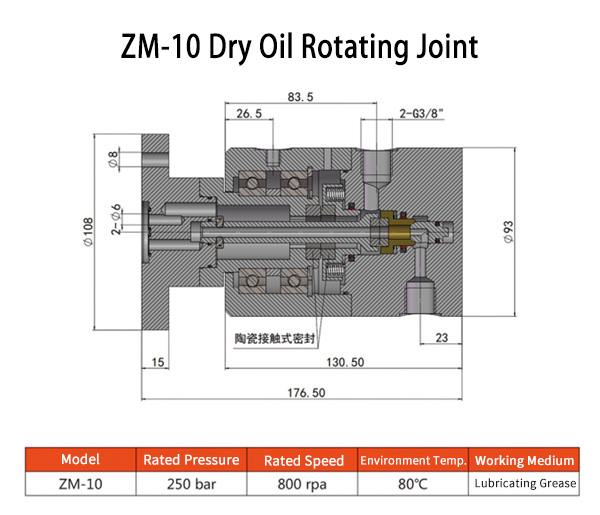

ZM-10 is a dry oil rotating joint which has two separate channels, with the ceramic contact seal axial rotary joint and equipped with automatic calibration compensation system, ensure the ceramic surfaces fully contact at all times. The shell is made of high strength aluminum alloy, the weight is very light. Due to the use of very durable ceramic contact sealing structure, to achieve a longer service life.

ZM-10 is a dry oil rotating joint which has two separate channels, with the ceramic contact seal axial rotary joint and equipped with automatic calibration compensation system, ensure the ceramic surfaces fully contact at all times. The shell is made of high strength aluminum alloy, the weight is very light. Due to the use of very durable ceramic contact sealing structure, to achieve a longer service life.

Features

●Sealed bearing, smooth operation.

●No need maintenance for bearings.

●With the design of automatic calibration compensation system.

●Extreme durable ceramic contact sealing structure.

ZM-10B is a high flow dry oil rotating joint with two separate channels. The joint housing is provided with a ceramic cover with self-centering function, the central shaft is fitted with a very durable seal, make it achieve good sealing effect. Cause the ceramic cover with high degree of finish and hardness, the sliding between the ceramic cover and the sealing parts is smoothly, greatly prolongs the service life of the joint. But during the operation process, because the seal and the ceramic cover friction contact, there is a heating problem, need to install a circulating colling water to eliminate it.

Features

●Precise bearing on both sides, smooth operation.

●Adopt self-centering ceramic cover and special seal design, low leakage and long using life.

●Cause the hollow spindle design of the main shaft, the central part can pass through the displacement sensor and other components.

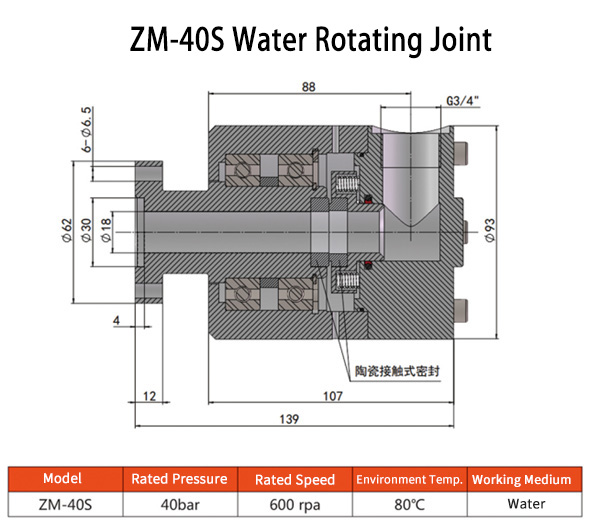

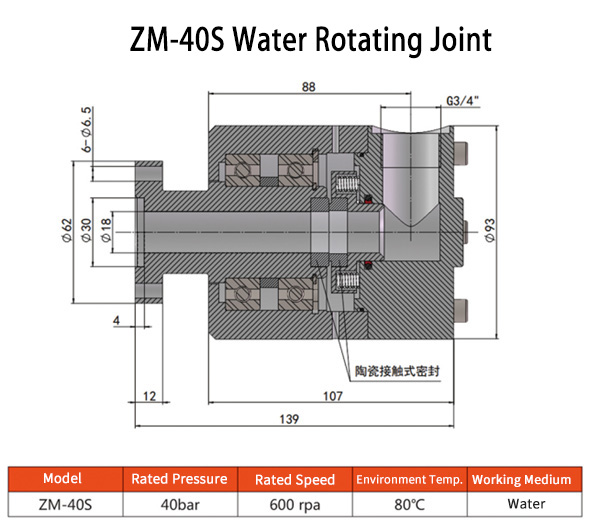

ZM-40S is a water rotating joint, the water flow through the center with single channel. Adopts ceramic contact seal design and equipped with automatic calibration compensation system, ensure the ceramic surfaces fully contact at all times, ensure no leakage. All parts adopt 304 stainless steel, equipped with ceramic bearing, ensure longer service life.

Features

●Ceramic bearing, long service life.

●Automatic calibration compensation system, no leakage.

●Extreme durable ceramic contact sealing structure.

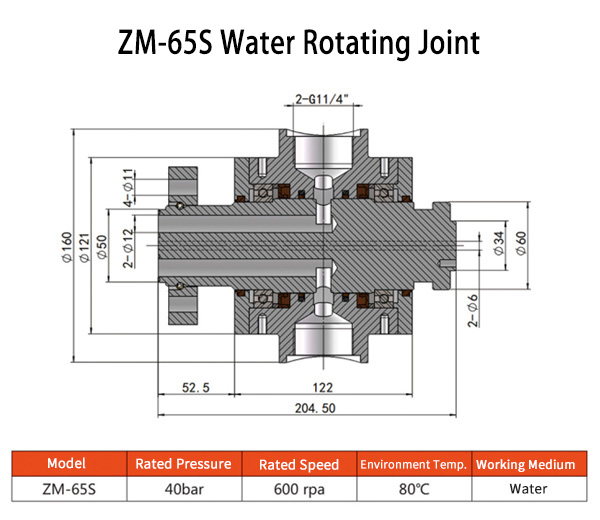

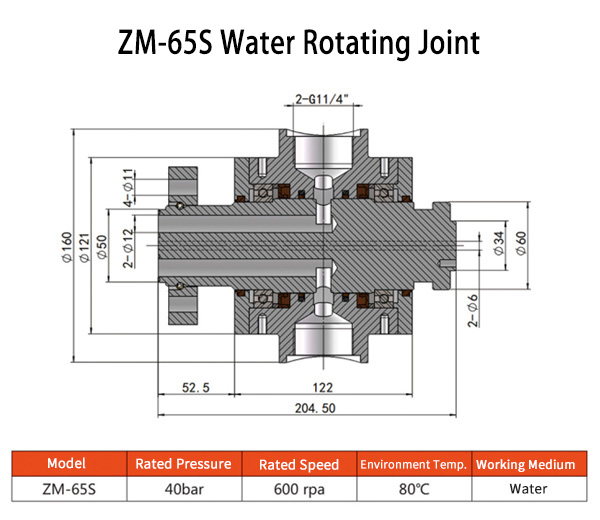

ZM-65S is a high flow water rotating joint with double channels in parallel. The shell equipped with very durable seals, at the same time, both sides are equipped with shaft seals for high speed and bearing pressure of 10bar, realized the double sealing effect. The contact surface between center shaft and sealing element adopts ceramic process, smooth and wear- resisting.

Features

●Ceramic bearing, long service life.

●Stainless steel resistant to corrosion.

●Multiple seals protect against leakage.

●Fitting surface adopts ceramic process with long service life.

Under the condition of high-speed operation, the ZM200 disc type hydraulic rotating joint can ensure the transmission of high-pressure oil to the hydraulic actuator steadily, make the system run stably and reliably. The fitting surface between the port plate and the central shaft as well as the surface between the shaft seal and the central shaft were processed by ceramic process, which make the smoothness and hardness of the fitting surface are greatly improved, prolong the service life of the joint.

Features

●Precise bearing on both sides, smooth operation.

●The fitting surface made by ceramic technology, wear-resistant, long using life.

●The flow rate up to 640L/min.

●High precision joint, medium should be filtered, cleanliness is not lower than NAS9 grade.

ZM200J hydraulic rotary joint use the small clearance between fixed parts and rotating parts, under the condition of high speed and high pressure to local change the flow area, cause a pressure loss of liquid flow, thus results in a very low leakage and returns to oil tank through the oil drainage port. This kind of sealing structure has high requirements for the geometrical size, surface machining precision and assembly of the parts.

Features

●Precise bearing on both sides, smooth operation.

●Non-contact and non-wear seal design.

●The fitting surface made by ceramic technology, long using life.

●Low turning torque produce less heat.

●High precision joint, medium should be filtered, cleanliness is not lower than NAS9 grade.

●Cause the hollow spindle design of the main shaft, the central part can pass through the displacement sensor and other components.

Features

●Sealed bearing, smooth operation.

●No need maintenance for bearings.

●With the design of automatic calibration compensation system.

●Extreme durable ceramic contact sealing structure.

ZM-10B is a high flow dry oil rotating joint with two separate channels. The joint housing is provided with a ceramic cover with self-centering function, the central shaft is fitted with a very durable seal, make it achieve good sealing effect. Cause the ceramic cover with high degree of finish and hardness, the sliding between the ceramic cover and the sealing parts is smoothly, greatly prolongs the service life of the joint. But during the operation process, because the seal and the ceramic cover friction contact, there is a heating problem, need to install a circulating colling water to eliminate it.

Features

●Precise bearing on both sides, smooth operation.

●Adopt self-centering ceramic cover and special seal design, low leakage and long using life.

●Cause the hollow spindle design of the main shaft, the central part can pass through the displacement sensor and other components.

ZM-40S is a water rotating joint, the water flow through the center with single channel. Adopts ceramic contact seal design and equipped with automatic calibration compensation system, ensure the ceramic surfaces fully contact at all times, ensure no leakage. All parts adopt 304 stainless steel, equipped with ceramic bearing, ensure longer service life.

Features

●Ceramic bearing, long service life.

●Automatic calibration compensation system, no leakage.

●Extreme durable ceramic contact sealing structure.

ZM-65S is a high flow water rotating joint with double channels in parallel. The shell equipped with very durable seals, at the same time, both sides are equipped with shaft seals for high speed and bearing pressure of 10bar, realized the double sealing effect. The contact surface between center shaft and sealing element adopts ceramic process, smooth and wear- resisting.

Features

●Ceramic bearing, long service life.

●Stainless steel resistant to corrosion.

●Multiple seals protect against leakage.

●Fitting surface adopts ceramic process with long service life.

中文

中文 ENGLISH

ENGLISH