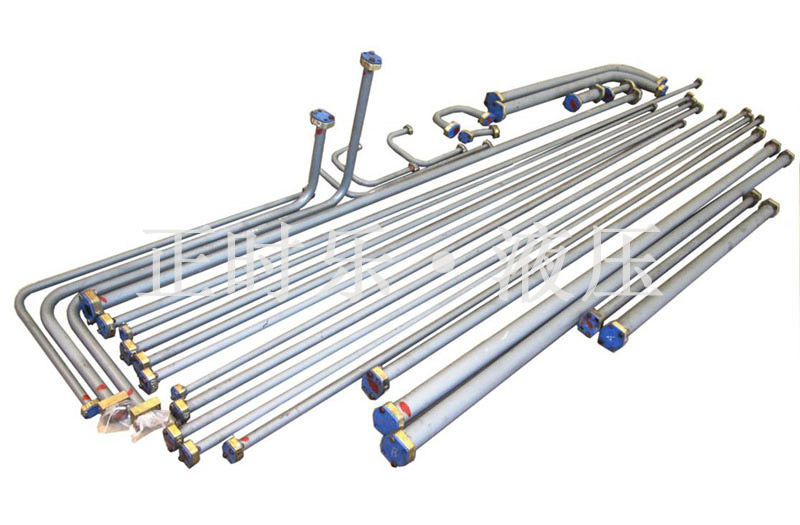

Free Welding Pipeline

Engineering Design

Determine the diameter, wall thickness and material of the pipe according to the flow and pressure.

According to the data and drawings provided by customers or our field measurement, establish 3D model, and determine the pipeline layout and parts list.

According to the pipeline layout and parts list, determine the parts drawing and prepare for pre machining.

Steel tube module

Packaging

Brazilian customer site inspection

Turkey installation site

Washing station

Product characteristics

Short construction period: the manufacturing, installation and flushing time of the pipeline are greatly shortened, which can save more than 2 / 3 time compared with the welding pipeline.

High cleanliness: avoid the blockage of the hydraulic system and the damage of the equipment caused by the falling off of the welding point and oxide layer, eliminate the long-term hidden danger of the system, and the cleanliness in the pipe is high, which can reach the nas7 level or above without long-time washing on site.

No leakage: through fastening, the deformation between the flared surface of the pipe end and the conical body of the joint is produced to achieve the sealing effect, which is very safe. No leakage caused by welding stress, especially for severe vibration.

Easy installation: fast and simple installation, no need to spend precious time to train professional welders.

No need for flaw detection: no welding points, so no need for X-ray flaw detection.

No pollution: avoid environmental pollution caused by pickling.

Easy to maintain: easy to remove, replace and add parts to the pipeline.

中文

中文 ENGLISH

ENGLISH